From PLA to Prop: How 3D Printing is Changing Cosplay

3D printing is certainly not new to the world of cosplay, but it continues to change the landscape now more than ever. Just 10 short years ago, 3D printers were mostly reserved for academic settings, community makerspaces, and the workshops of the most dedicated hobbyists. Now, you can pick one up at MicroCenter for $99 or commission a resin print on demand for as low as $15 on Fiverr. The rapid growth of the hobby has led to increased innovation not only from the industry, but also from individual cosplayers and hobbyists in how they use 3D printing in their day-to-day lives.

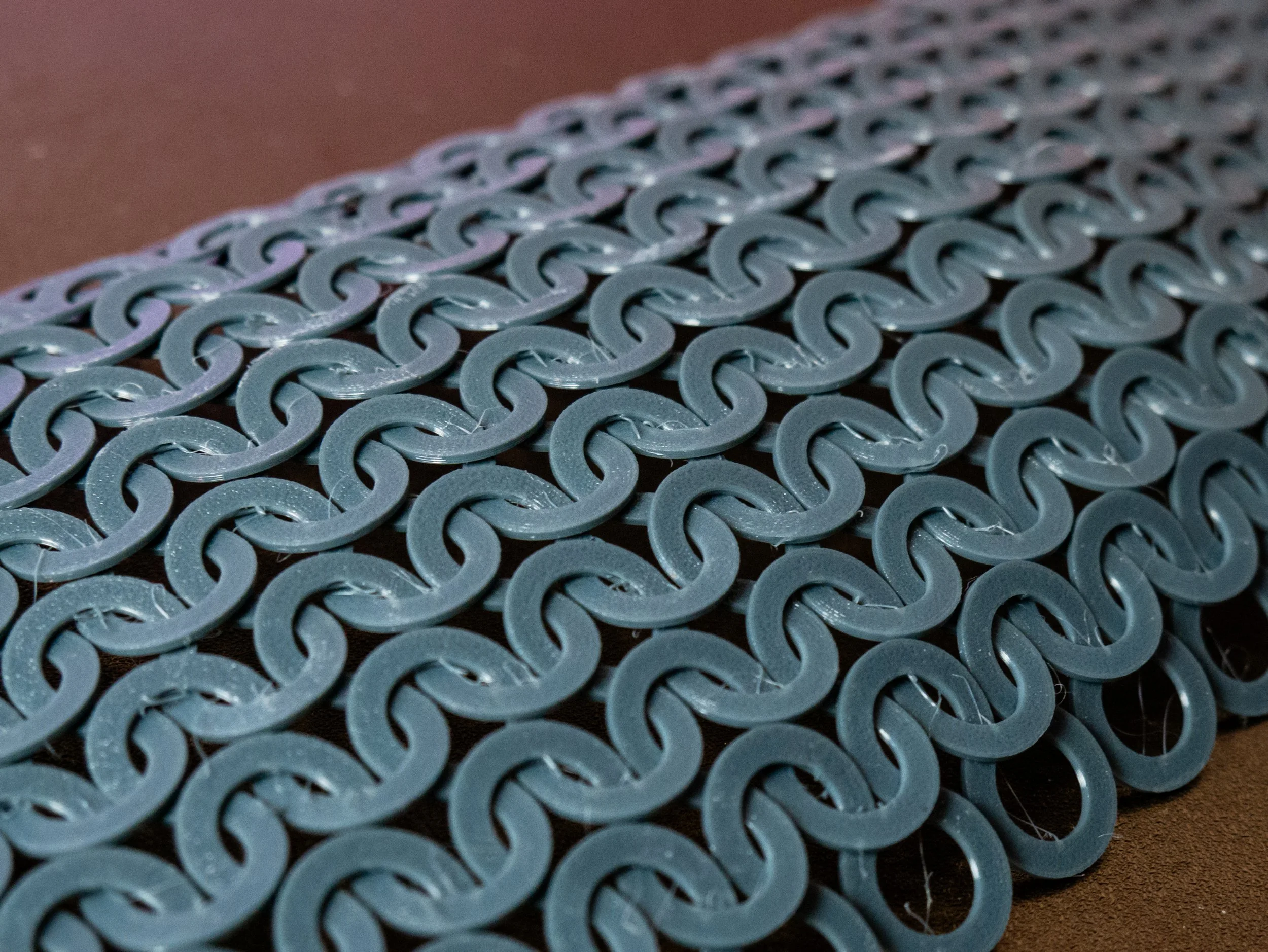

Every cosplayer knows the importance of flexibility. It’s one of the reasons EVA foam grew so much in popularity for building armor. Flexible 3D printing filaments such as TPU continue to gain popularity as well. Cosplayer Ben Eadie developed a pattern that can be woven together to easily and swiftly produce costume chainmail, tested by Adam Savage himself! Although originally developed for EVA foam, Eadie also created a 3D model of the pattern that can be printed with flexible filaments. Below is a sample I 3D printed and wove myself using Flex PLA.

3D printed chainmail

We have seen 3D printed armor and props take the cosplay world by storm. Frank of Frankly Built (featured previously in Creative Cosplays Magazine) grew to over a million subscribers on YouTube and over 2 million followers on TikTok by teaching and talking about 3D printing cosplay armor, particularly his Iron Man suits. He has had the pleasure of experiencing some of the most advanced 3D printing technology being developed. For example, he’s spoken about seeing metal printing, a process similar to resin printing where a laser is used to fuse and build up metal powder. However, “The 3D printed Lamborghini is probably the craziest thing I’ve seen,” he told me, referring to a fully working vehicle printed by physicist Sterling Backus and his son on a common, at-home Creality 3D printer. Companies like Stratasys push the envelope even further, developing industrial machines capable of printing fully realistic prop foods in full color.

Beyond armor and chainmail, the world of fabric and sewing has adopted 3D printing, too. TikTok creators Variable Seams, Sew Printed, and Sierra Sandison create intricate, 3D printed fashion collections ranging from geometric dresses incorporating mirrors to colorful light-up handbags. They use the printed plastic as the “fabric” itself, but artists can also 3D print on top of regular fabric. Designer and artist David Shorey of Shorey Designs has popularized a technique that involves printing scales and other 3D shapes onto a layer of mesh such as nylon tulle to fuse the plastic into a fully flexible and sewable segment of fabric. Of course, I would be remiss if I didn’t mention using 3D printing in a more traditional way as well: by printing accessories such as ornaments and buckles that are attached to sewn pieces.

3D printed buckle for a cosplay jacket

As manufacturers produce speedier printers with multi-filament capabilities, cosplayers are adapting to find new and creative ways to apply 3D printing. Some hobbyists are using it to skip the mold-making process for casting with resin by just designing and printing the mold itself. Others enjoy printing full sets of armor, helmets, or swords from their favorite media. In any case, cosplayers have embraced 3D printing with open arms, affirming that the future of cosplay is, undoubtedly, 3D.